Electrolytic Iron Powder

Price 45 INR/ Kilograms

Electrolytic Iron Powder Specification

- Metal Type

- Pure Iron

- Melting Point

- 1535C

- Grade

- Electrolytic Grade

- Purity(%)

- 99.5% min

- Usage & Applications

- Pharmaceuticals, chemical industries, soft magnetic cores, laboratory reagents

- Particle Size

- Up to 100 mesh (custom sizes available)

- Boiling point

- 2750C

- Material

- High Purity Electrolytic Iron

- Shape

- Powder

- Chemical Composition

- Fe: 99.5% min, C: 0.01% max, S: 0.01% max, P: 0.01% max, Si: 0.02% max, Mn: 0.01% max

- Density

- 3.0 Gram per cubic centimeter(g/cm3)

- Size

- Fine Powder

- Weight

- 25 kg (standard), customized packing available Kilograms (kg)

- Color

- Grey

- Solubility

- Insoluble in water

- Reactivity

- Stable under ambient conditions

- Apparent Density

- 2.4-3.0 g/cm³

- Moisture Content

- < 0.05%

- Storage Conditions

- Store in dry, cool place, away from alkalis & acids

- Conductivity

- High, suitable for magnetic and electrical purposes

- Production Method

- Electrolytic deposition and pulverization

- Sieve Analysis

- 99% passing through 100 mesh sieve

- ISO Certification

- ISO 9001:2015 Certified

- Packing

- Polyethylene bags inside steel drums or customized

Electrolytic Iron Powder Trade Information

- Minimum Order Quantity

- 25 Kilograms

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Electrolytic Iron Powder

The purest form of iron is called electrolytic iron, which is a result of chemical electrolysis of solution that comprises iron compound, such as ferrous sulphate. There are many industrial applications of this iron, because of its purity. We, Kalyan Industries makes available electrolytic iron powder in different mesh sizes to benefit clients across several industrial sectors. The powder is used in industrial processes, like fortification, manufacturing iron nutrition supplements, production of drugs, chemical intermediates development, color complexes and dyes production, magnetic alloys production and diamond blades fabrication. Electrolytic iron powder is processed in large amount to fulfill the requirements of many clients. This powder is well-packaged before dispatching to be sold in the market.

- Food industry

- Nutrition related manufacturing

- Pharmaceuticals manufacture

- Chemicals

- Paints & dyes

- Printing sector

- Magnetic alloys

- Diamond cutting tools industry

High Purity and Consistency

Electrolytic Iron Powder stands out due to its exceptional purity (minimum 99.5% Fe) and uniformity, achieved via electrolytic deposition followed by fine pulverization. This ensures consistent performance, making it a preferred choice for critical applications in electronics, pharmaceuticals, and research laboratories.

Wide Range of Industrial Applications

Thanks to its stability, high electrical conductivity, and soft magnetic characteristics, this iron powder is well-suited for use in soft magnetic cores, chemical synthesis, pharmaceutical formulations, and as laboratory reagents. Its versatility meets the demands of various sectors, from manufacturing to cutting-edge scientific research.

Customizable Packaging and Sizing

Standard packaging consists of polyethylene bags placed in steel drums, usually in 25 kg quantities. However, custom packing and tailored particle size distributions are available to accommodate specific industry and project requirements, ensuring convenience and minimizing product wastage.

FAQs of Electrolytic Iron Powder:

Q: How is Electrolytic Iron Powder produced?

A: Electrolytic Iron Powder is manufactured through a process that involves electrolytic deposition of pure iron, followed by pulverization to achieve fine particle sizes. This method ensures high purity, consistency, and a controlled particle size distribution.Q: What are the main industrial applications of this iron powder?

A: This iron powder is widely used in pharmaceuticals, chemical industries, soft magnetic cores, laboratory reagents, and various electrical and magnetic applications, thanks to its high conductivity, stability, and purity.Q: When should I choose electrolytic grade iron powder over other grades?

A: Electrolytic grade iron powder is ideal when your application demands exceptional purity, reliable conductivity, and consistent quality, as required in pharmaceuticals, electrical components, and high-precision laboratory work.Q: Where should I store Electrolytic Iron Powder to maintain its quality?

A: Store the powder in a dry, cool place, away from alkalis and acids, as these can compromise its stability and purity. The recommended packaging, such as polyethylene bags inside steel drums, helps preserve its condition during storage.Q: What benefits does the sieve specification of 99% passing through 100 mesh provide?

A: This fine particle size ensures excellent flow properties, uniform mixing, and enhanced reactivity in various chemical and industrial processes, improving both efficiency and product quality.Q: How is the product packaged, and are custom options available?

A: The standard packing involves polyethylene bags secured within steel drums, typically in 25 kg units. Custom packaging and particle size requirements can be accommodated based on user needs.Q: What measures ensure the safety and stability of Electrolytic Iron Powder during storage and usage?

A: With a moisture content below 0.05% and stable reactivity under ambient conditions, Electrolytic Iron Powder remains safe and consistent when stored appropriately, reducing risks of clumping or contamination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Iron Powder Category

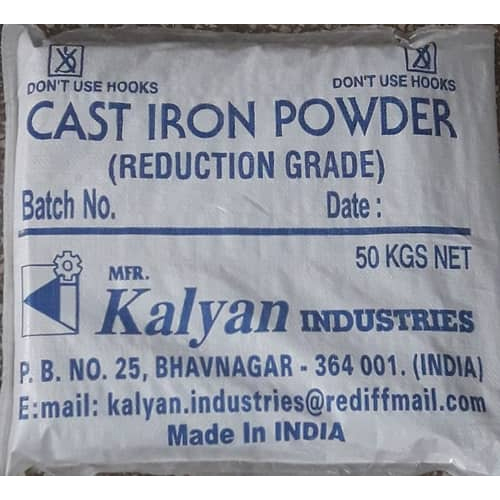

Cast Iron Powder

Price 45 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Boiling point : 2862C

Size : Fine powder

Density : 7.2 Gram per cubic centimeter(g/cm3)

Particle Size : 150 mesh

Cast Iron Powder 30 60 Mesh

Minimum Order Quantity : 500 Kilograms

Boiling point : Above 2500C

Size : Fine Powder

Density : 7.8 Gram per cubic centimeter(g/cm3)

Particle Size : 3060 Mesh

Reduction Grade Cast iron Powder

Price 45 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Boiling point : Above 2700C

Size : Various sizes (customizable as per requirement)

Density : 7.3 Gram per cubic centimeter(g/cm3)

Particle Size : 150 to 300 Mesh

Send Inquiry

Send Inquiry